SEAMLES STEEL TUBES FOR HIGH-PRESSURE BOILERS

Seamless steel tubes for high pressure boilers include GB/5310-2007 standard, ASME SA-106/SA-106M-2015,ASTMA210(A210M)-2012, medium carbon steel seamless steel tubes for boilers and superheaters, ASME AS – 213 / SA – 213 M, ASTM A335 / A335M – 2018.

GB/T5310-2017 is mainly used to manufacture high pressure and above pressure steam boiler pipes and other high-quality carbon structural steel, alloy structural steel and stainless heat resistant steel seamless steel pipe. High quality carbon structural steel steel 20g, 20mg, 25mg. Alloy structural steel steel 15MOG, 20MOG, 12CrMOg, 15CrMOg, 12Cr2MOG, 12CrMOVG, 12Cr3Movsitib, etc

Rust heat resistant steel commonly used 1Cr18Ni9, 1Cr18NillNb

Main materials corresponding to GB/T5310 standard: 20G,20MnG,25MnG,16Mn, 15Mog.20MOG, 15CrMo,15CrMoG,12CrlMoV,12Cr1MoVG,Cr5Mo, 10CrMo910 main test requirements: in addition to ensuring chemical composition and mechanical properties, to do water pressure test, to do flaring, flattening test. In addition, the microstructure, grain size and decarburization layer of finished steel tubes are also required. Delivery status: Heat treatment

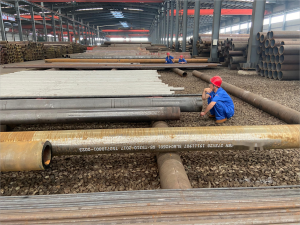

When seamless steel pipes are shipped to customer countries, there can be different packaging methods according to customer’s different needs. Recently, for the goods we sent to Vietnam, the customer chose casing transportation to reduce the volume of goods and save packaging costs. We also have PVC packing, baling packing, iron frame packing, casing packing and so on. You can check our website for other packing methods. Alloy steel tube, seamless steel tube SA106 GR.B, oil tube K55,L80, etc., can adopt the above packing method.