Seamless alloy steel Pipe ASTM A335

ASTM A335 P5 Is An Alloy Steel Seamless Ferritic High Temperature Pipe Of American Standard. Alloy Tube Is A Kind Of Seamless Steel Tube, Its Performance Is Much Higher Than The General Seamless Steel Tube, Because This Kind Of Steel Tube Contains More C, The Performance Is Less Than The Ordinary Seamless Steel Tube, So The Alloy Tube Is Widely Used In Petroleum, Aerospace, Chemical, Electric Power, Boiler, Military And Other Industries.

Alloy Steel Pipe Contains Substantial Quantities Of Elements Other Than Carbon Such As Nickel, Chromium, Silicon, Manganese, Tungsten, Molybdenum, Vanadium And Limited Amounts Of Other Commonly Accepted Elements Such As Manganese, Sulfur, Silicon, And Phosphorous

Corresponding Domestic Alloy Steel :1Cr5Mo GB 9948-2006 “Seamless Steel Pipe Standard For Petroleum Cracking”

- Payment:30% Deposit, 70% L/C Or B/L Copy Or 100% L/C At Sight

- Min.Order Quantity:1 PC

- Supply Ability:Annual 20000 Tons Inventory Of Steel Pipe

- Lead Time:7-14 Days If In Stock, 30-45 Days To Produce

- Packing:Black Vanishing, Bevel And Cap For Every Single Pipe; OD Below 219mm Need To Pack In Bundle, And Each Bundle No Exceed 2 Tons.

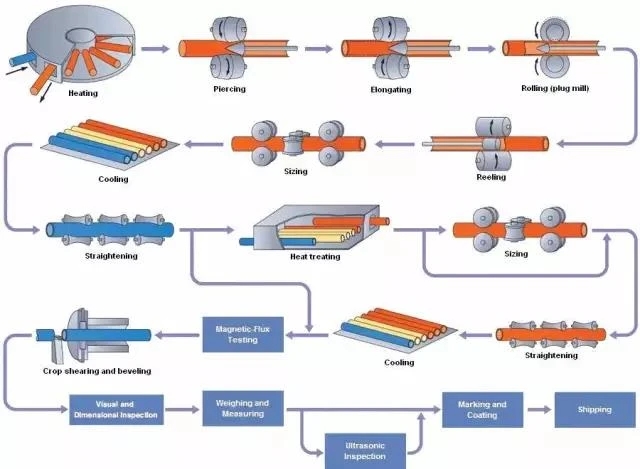

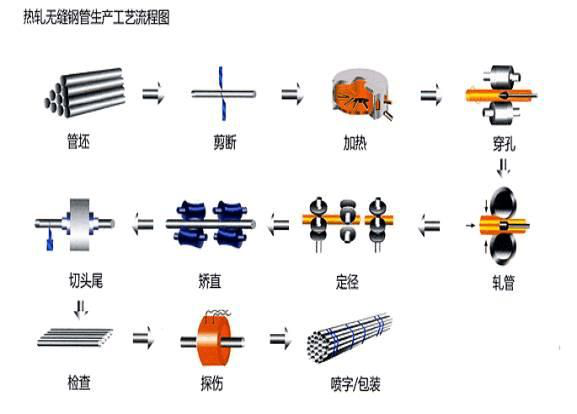

Production process:Hardness Test:

1. Hot rolling (extruded seamless steel tube) : round tube billet → heating → perforation → three-roll cross rolling, continuous rolling or extrusion → tube stripping → sizing (or reducing) → cooling → straightening → water pressure test (or defect detection) → marking → storage

2. Cold drawing (rolling) seamless steel tube: round tube billet → heating → perforation → heading → annealing → pickling → oiling (copper plating) → multi-pass cold drawing (cold rolling) → blank tube → heat treatment → straightening → water pressure test (flaw detection) → marking → storage

Packing:

Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.